Production Engineering

H-one actively proposes products that are achieved by break-through technologies such as super-high strength steel stamping, a new production technique called 3DQ, and metal separator that is a new environmental product.

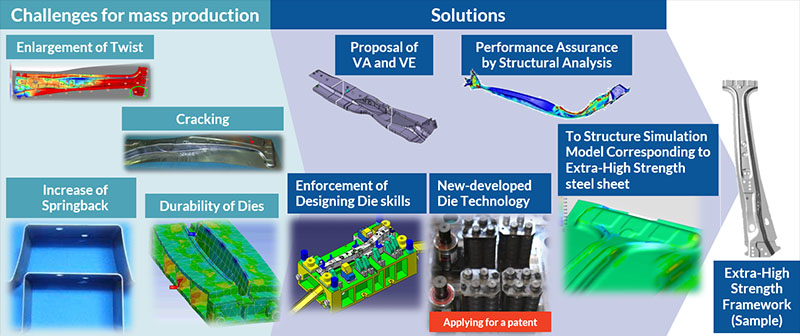

Application of super-HSS 1,180Mpa to body frame mass production

H-one has succeeded in mass production of super-HSS (1,180Mpa) framework parts, which had been regarded as the limitation of stamping technology, and now vehicles built with super-HSS are driving on the roads. We have also broken the technology barrier and we are ready for mass production of stronger framework parts using superior-HSS (1,470MPa).

Activity toward mass production

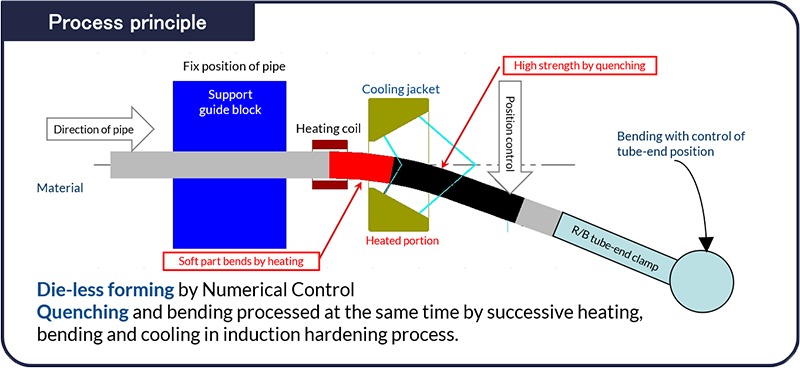

3DQ (three-dimensional hot bending and direct quench pipes)

H-one has developed the 3DQ technology for square/rectangular pipes in collaboration with Nippon Steel Corporation and Nippon Steel Pipe Co., Ltd. and applied the technology to the Honda NSX. The newly developed pillar is narrower in width and provides superior visibility to the driver. It also offers high precision geometry that is required for body framework parts and the 1,500MPa level of strength that achieves both passenger safety and weight reduction.

Possible application examples

Advantage of 3DQ

- High frequency quenching achieves the same strength as hot stamping

- The closed cross-section structure enables designing of high-strength frames with a smaller cross-section.

- 3DQ can process various steel pipes with various shapes.

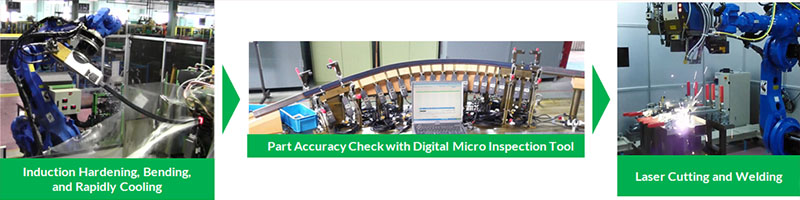

Machining process

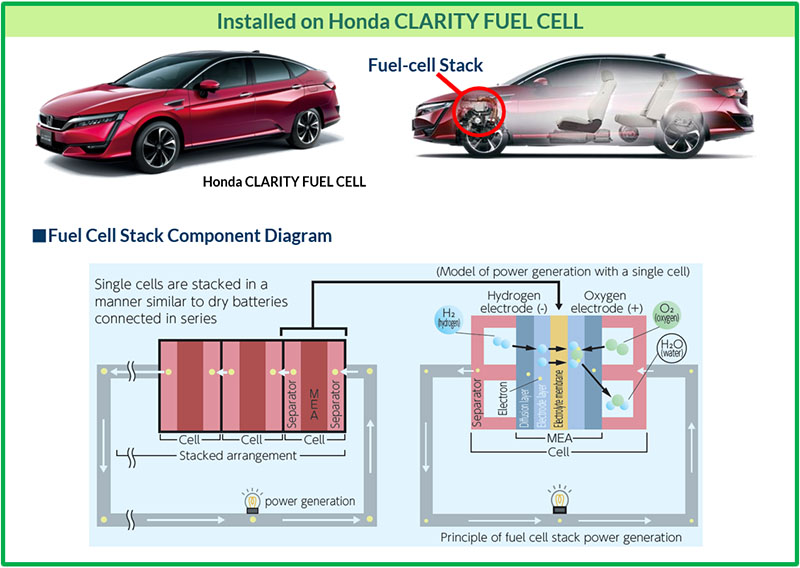

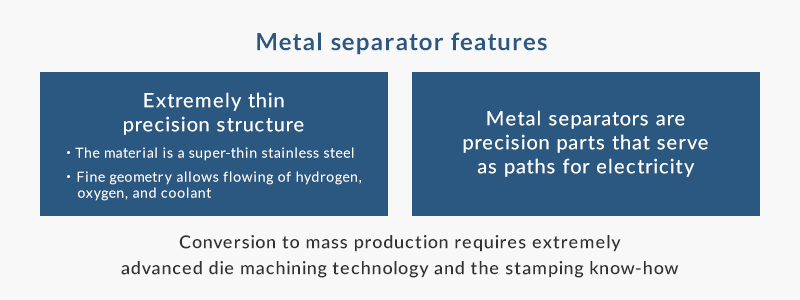

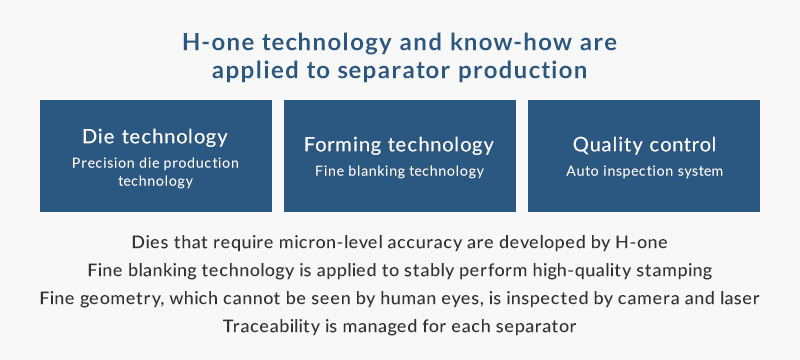

Metal separators for fuel cell vehicles

Metal separators are fuel cell stack components, which are mounted on Honda’s new fuel cell vehicle “Clarify Fuel Cell.” The metal separators having fine stainless steel mesh sandwich a membrane that generates electricity by the chemical reaction of hydrogen and oxygen. The separators serve as passages for hydrogen and oxygen as well as generated electricity. Several hundreds of separators are used per vehicle to generate powerful electricity. Each metal separator is extremely thin to reduce the FC stack size and it has a unique fine geometry to uniformly distribute hydrogen and oxygen over the separator, and our know-how is utilized to stably stamp and form this geometry in mass production.