Product Designing

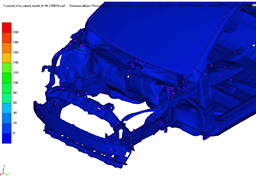

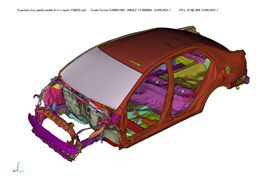

Collision, strength, and rigidity simulations

To evaluate our products’ collision, strength, rigidity performance, etc. in the design phase, we work with our customers to simulate and analyze the body frame performance.

Whole vehicle analyses are jointly conducted with our customers as our products are joined with other companies’ products. To analyze the performance of our products only, we run simulations internally.

Collision analysis

Strength analysis

Rigidity analysis

Guest engineering activity

Our body framework experts participate in our clients’ new model development projects from the initial design phase as guest engineers (design-in). The guest engineers’ role is to reflect H-one’s body framework engineering capability and philosophy to the design drawings while satisfying clients’ specifications and requirements. This way, we can speedily propose feasible solutions to challenges that are unique to each project. Our associates are consistently striving to evolve drawings while enjoying the excitement of car making.

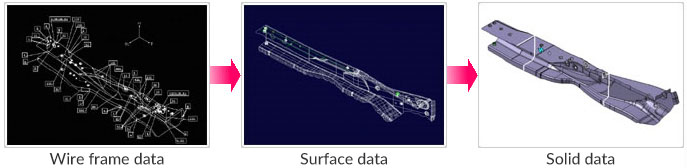

3D designing

H-one is an early adopter of 3D designing, for which the data have evolved from wire frame data to surface data, and then to solid data. The benefit of 3D designing is that a part geometry can be understood easily so that the manufacturability can be virtually verified. 3D designing contributes to speedy product development as its data are applied to stamping simulations, robot simulations, die data creation, etc.

Evolution of 3D designing

Prototyping

During prototype development, we ensure that our products precisely meet clients’ criteria specified by the drawings and the manufacturability is verified at an early stage. During product prototyping, we inspect all prototype products before delivering them to our clients. During manufacturability verification, we use simulations and production-intent welding robots to verify mass producibility as well as the noncontact measurement technology to further improve the accuracy of actual products.

Related Contents