Environment

- Philosophy

- Action Guidelines

- Environmental Organization

- Environmental Management System

- ISO14001 Acquisition Status

- Environmental Objectives and Achievements

- Environmental Activities

H-one Group Environmental Policy

Philosophy

Based on our management philosophy, the H one Group aims to contribute to the sustainable development of society and achieve a decarbonized society by striving to reduce the environmental impact of all our business activities.

Action Guidelines

- We will understand the environmental needs of society and our customers and strive to develop and produce products that exceed expectations.

- We will strive to conserve resources and energy at every stage of our product’s life cycles.

- Each and every member of our group will commit to sustainable use of resources, addressing climate change, and protecting biodiversity and ecosystems in consideration of regional characteristics.

- We will comply with legal requirements and individually agreed on standards, and work with stakeholders in the supply chain and as a member of society to resolve environmental issues.

- We will properly recognize the impact of our business activities on the environment, strive to continuously reduce environmental risks by optimizing our promotion system in accordance with our environmental management system by working toward our environmental targets.

Environmental Organization

We have established and maintain an environmental management organization at each of our business sites, and while we place emphasis on CO2 reductions, we are promoting environmental activities aimed at energy saving, resource saving, and waste reduction in conjunction with our businesses. Persons responsible for respective business sites meet regularly, where the status of activities, issues, and future policies are shared, and activities are taken in each department. In addition, internal environmental audits are conducted on a yearly basis to clarify issues and strive for their improvements.

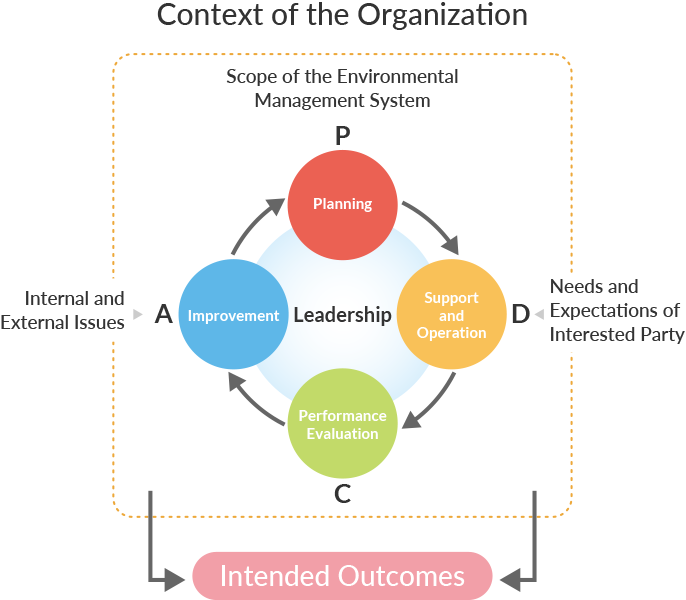

Environmental Management System

We take the Environmental Management System (EMS) based on ISO14001 as a basis for environmental activities. We reduce environmental burdens in our business activities by efficiently following the PDCA cycle of the EMS and continuously evolve the EMS.

Regarding the contents of environmental activities and achievements of activities, a management review (by the management officer) is conducted on a yearly basis. In addition, a company-wide conference is held twice a year, where persons responsible for environmental management meet from domestic business sites and opinions are exchanged and discussions are made on activities at each site. We promote improvement linkages with our businesses by confirming progress with respect to environmental objectives, sharing excellent activities, discussing future activities, etc.

ISO14001 Acquisition Status

| Facility | Location | Reviewing Organization |

|---|---|---|

| Head Office/Business Management Operations | Saitama City, Saitama | JARI-RB |

| Business Management Operations Haga | Haga Town, Haga County, Tochigi | |

| Development Business Operations Karasuyama | Nasu Karasuyama-shi, Tochigi | |

| Development & Engineering Center | Koriyama City, Fukushima | |

| Development & Engineering Center (Maebashi) | Maebashi City, Gunma | |

| Koriyama Factory | Koriyama City, Fukushima | |

| Maebashi Plant | Maebashi City, Gunma | |

| Ota Factory | Ota City, Gunma | |

| Kameyama Plant | Kameyama City, Mie | |

| Konan Factory | Konan City, Shiga | |

| Bungotakada Factory | Bungotakada City, Oita |

Scope of certification includes all of our products and activities.

Environmental Objectives and Achievements

Achievements of FY2024

We promote initiatives toward reducing environmental burdens by setting environmental objectives common to all domestic business sites concerning the following items:

| Item | FY2024 | Target of FY2025 | |||

|---|---|---|---|---|---|

| Target | Examples of Activity | Achievement | |||

| Energy Saving | Saving Energy (Electricity, Gases, Gasoline, Kerosene, etc.) Used for Production Activities | compared to FY2019 15.0% Reduction in basic unit |

|

compared to FY2019 30.4% Reduction in basic unit |

compared to FY2019 18.0% Reduction in basic unit |

| compared to FY2019 15.0% Reduction in emissions |

compared to FY2019 11.9% Reduction in emissions |

compared to FY2019 18.0% Reduction in emissions |

|||

| Waste Reduction | Reduction of Amounts of Waste Generated in Facilities | compared to FY2019 5.0% Reduction in generated amounts |

|

compared to FY2019 9.5% Increase in generated amounts |

compared to FY2019 6.0% Reduction in generated amounts |

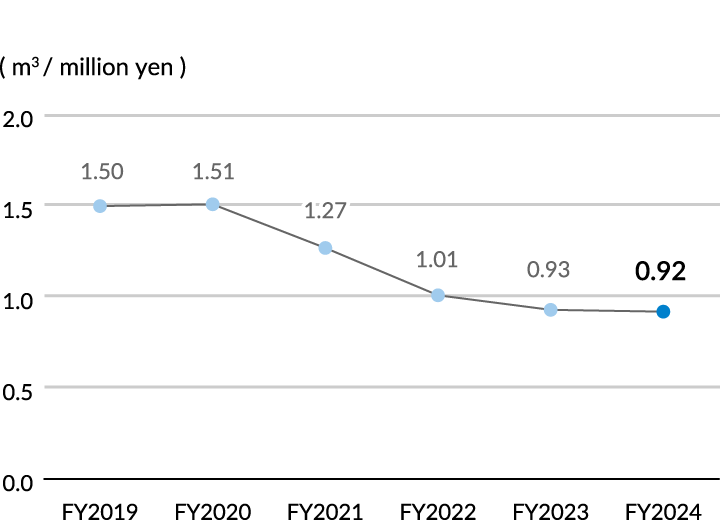

| Water Usage Reduction | Reduction of Amounts of Water Used in Facilities | compared to FY2019 5.0% Reduction in basic unit |

|

compared to FY2019 38.9% Reduction in basic unit |

compared to FY2019 6.0% Reduction in basic unit |

- * Totaling period:April 2024 – March 2025; Total value of all domestic business sites

-

*

The basic unit refers to emissions per specific unit, such as production volume. We use sales amounts that are highly relevant to energy consumption as the denominator.

It can be said that activities are more efficient the more the basic unit decreases. - * We set a reduction target of each item in the medium term (April 2023 – March 2026), where the base year is FY2019.

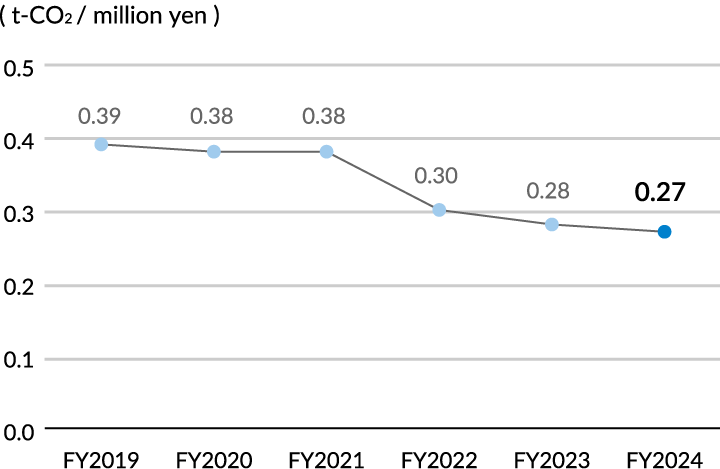

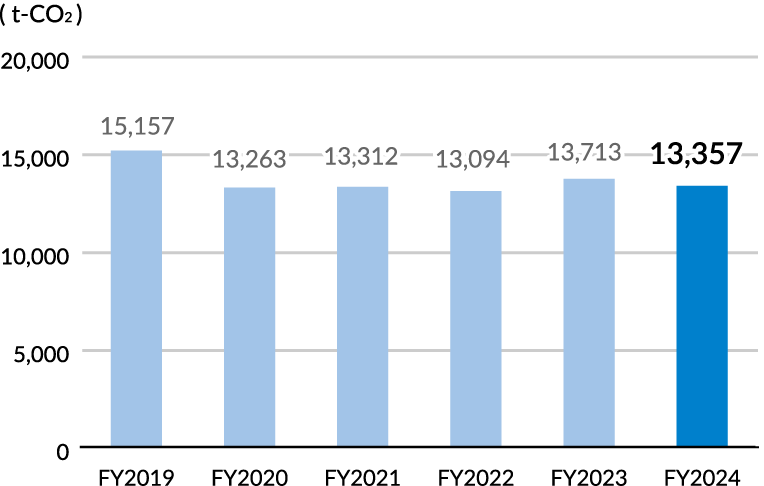

CO2 Emissions by Production Activities

Transition of basic unit

Transition of emissions

(Location-based, the fixed factor of electricity of 0.378t-CO2/MWh is used)

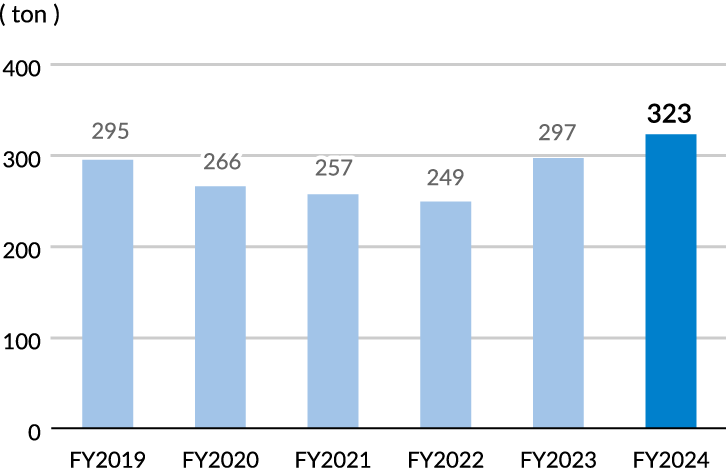

Amounts of waste generated

Transition of amount of generation

Amounts of water used

Transition of basic unit

Environmental Activities

ISO14001: 2015 renewal audits

We have obtained ISO14001 certification at all domestic business sites.

In FY2019, we changed our management system certification organization to the Japan Automobile Research Institute, Registration Body (JARI-RB), and we underwent an audit for renewal and the certification was renewed and continued.

Environmental education

For appropriate operation of the environmental management system, a working-level understanding is essential. Employees who have passed the auditor exam authorized by CEAR (currently JRCA), which is a personnel certification organization for ISO14001 auditors, plays a central role in providing environmental education for establishing a management system.

Examples of Environmental Education Provided in FY2024

| Item | Target | Number of Attendees | Contents |

|---|---|---|---|

| Specialized training for managers of EMS departments | Department managers Promoters |

57 | Newly appointed as the manager of EMS department Operation of each department based on the EMS regulations |

| Hierarchical training | Promoted persons | 36 | Environmental knowledge required of each hierarchical level |

*Educational materials related to environmental laws are posted on the company intranet and are always available for viewing.

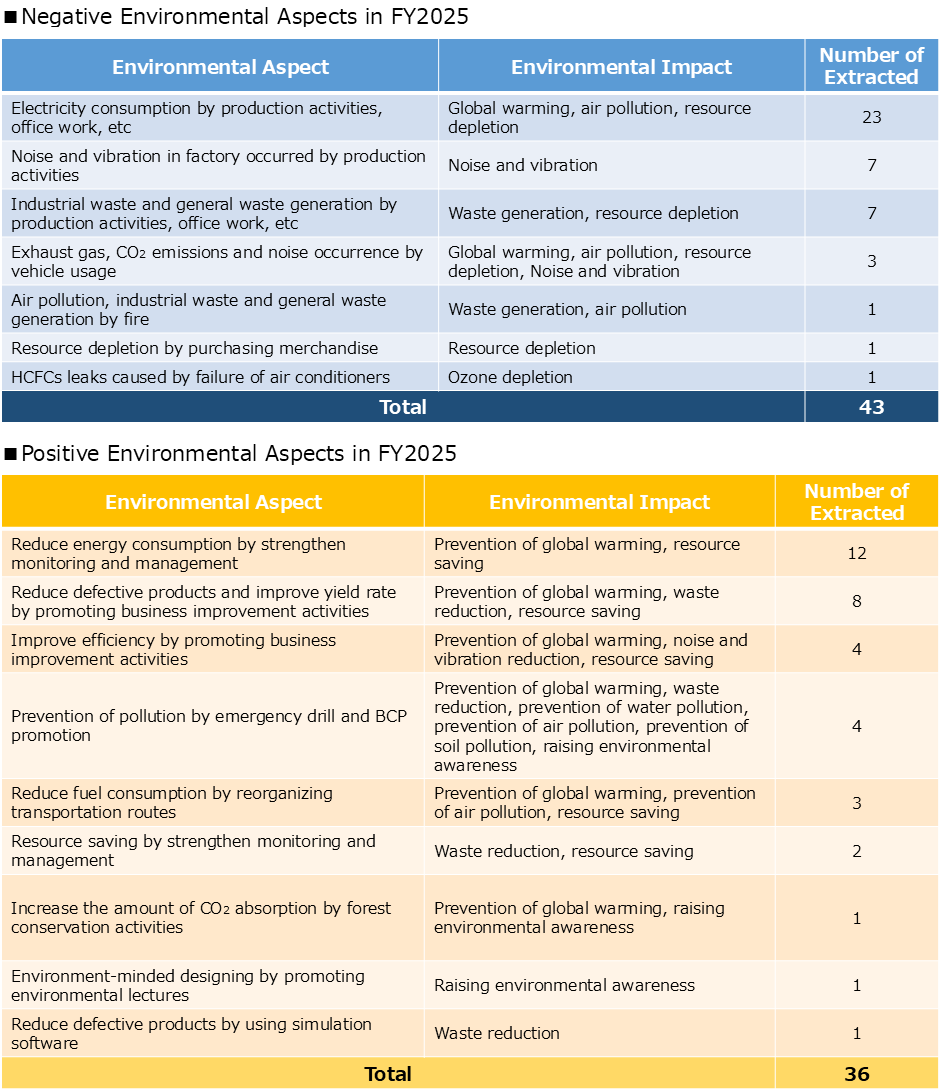

Extraction and management of environmental aspects

We consider that management of environmental aspects affecting the environment is particularly important in operating an environmental management system. We regularly extract and evaluate environmental aspects in departments, and identify those heavily affecting the environment as significant environmental aspects, which are targeted for priority management. For minimization of the environmental impact and promotion of proper initiatives, it is necessary to evaluate overall operations and identify environmental aspects from a broad perspective in terms of life cycles.

Classification of Significant Environmental Aspects

Study Session Targeting Employees

An environmental regular study session targeting all employees has been held on a yearly basis since FY2017, with the preparation of dedicated educational materials that compile knowledge necessary for correct understanding of global warming problems as well as environmental activities and environmental objectives we are addressing in-house.

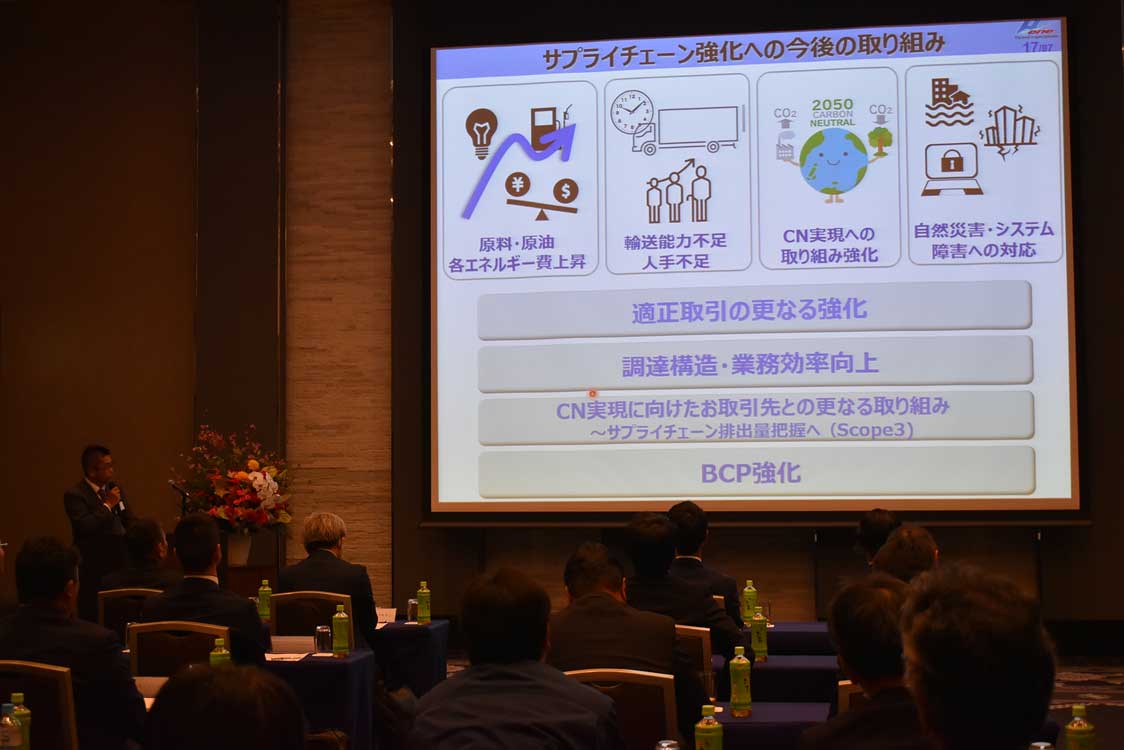

Initiatives in the Supply Chain

We have been promoting energy-saving initiatives aiming to reduce CO2 emissions jointly with our business partners. Since FY2016, we have expanded it to the entire domain of CSR, and enhanced initiatives in the supply chain. During the COVID-19 pandemic, the online briefings were held. From FY2024, we have held them face-to-face, with many business partners participating. We will continue to strive for further entrenchment in cooperation with our business partners.