Products

H-one Frames contribute to the future of mobility society

We create high-performance automotive frames for safety, comfortability and earth friendliness.

- Automobile Frames

- Special Products Born from H-one R&D

- Dies and Welding Equipment

- Motorcycle, Power Products, etc.

Automobile Frames

- Bulkhead

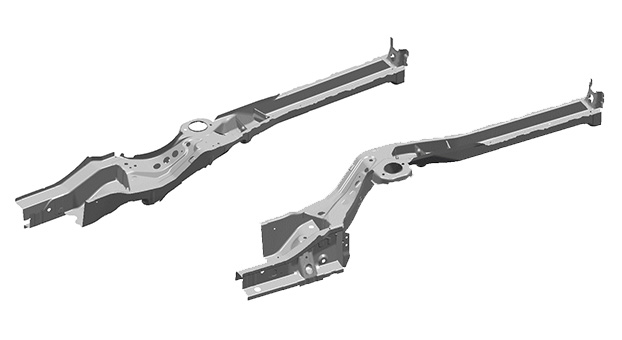

- Side Frame

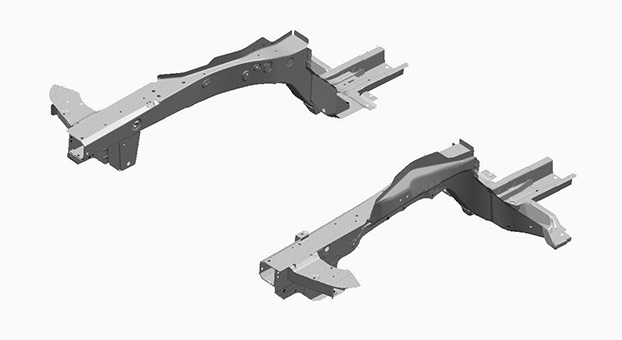

- Rear Frame

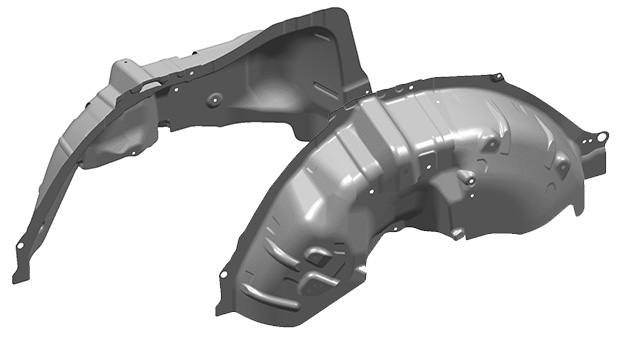

- Rear Wheelhouse

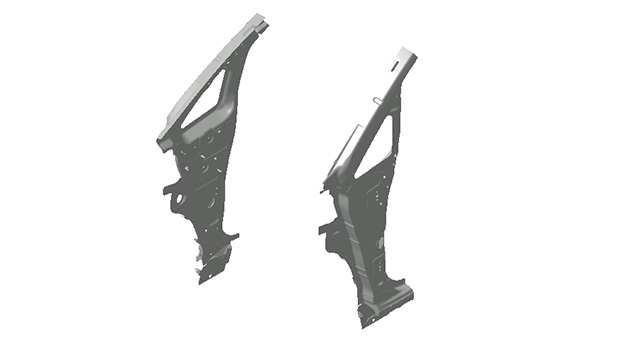

- Pillar

- Door Beam

- Cross Member

- Inside Sill

- Wheelhouse

- Floor Frame

Front Bulkhead Comp

The front bulkhead is located at the front of the automobile white body and partitions the engine room. Radiator, condenser, head lights, etc. are mounted on the front bulkhead at the automobile assembly plant. Because the front bulkhead directly affects the design of the automobiles, high precision is required. The front bulkhead is designed with a closed cross-section structure to enhance the rigidity of the whole vehicle.

Front Side Frame Comp

These frames extend from the front bumper to the front of the cabin on both sides of the engine. While supporting the engine which is the largest and heaviest component of the automobiles, it also takes a roles to enhance the whole strength and rigidity of the automobiles. In case of a collision, they absorb and disperse the shock backward, drop the engine downward so it will not be pushed into the cabin, and are designed so the frame itself will crumple on the impact. To provide both strength and crushable feature in one product, different types of steels are laser-welded together into a tailored blank so that various geometries can be achieved.

Rear Frame Comp

The rear frames run from the rear seat to the rear bumper. They require strength and rigidity to protect the cabin and fuel tank during collision. To maintain rigidity while the distance between the frames is expanded to give occupant comfort and variety for seat layouts, the shape is complex and rugged, requiring high forming technology.

Rear Wheelhouse Comp

The dome-shaped wheelhouse shrouds the tire from the cabin side. Because thin materials are used to achieve weight reduction, advanced deep drawing technology needs to be applied.

Pillar Comp

The pillar is a column reaching from the cabin floor to the roof. From the front windshield, they are called A-pillar, B-pillar, or C-pillar respectively. In past years, the main role was to hold the roof and the doors, but now the critical role is to determine collision safety performance. While maintaining the openings such as doors and tailgates, it disperses the energy during collision, prevents the cabin from collapsing, and maintains survival space for the occupants. Along with the required strength, a shape that will not obscure vision is also required. H-one has realized narrow but strong pillars by adopting stamping technology for super-high strength steel (super-HSS) that is stronger than regular HSS.

Door Beam

The door beams protect occupants by instantaneously and effectively absorbing the energy of impact upon lateral collision.

H-one applies a unique quenching process to steel pipes to significantly enhance the strength, while making them lighter at the same time.

Special Products Born from H-one R&D

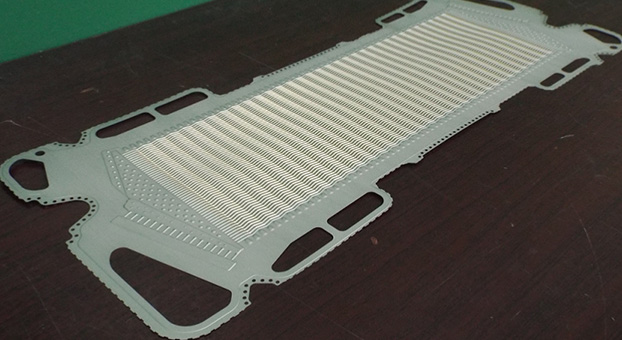

Metal Separator

Metal separators are a component of fuel cell stacks mounted in fuel cell vehicles. This product is extremely thin stainless steel having fine geometry for hydrogen, oxygen, and coolant to flow, to which our precision punching technology and precision die production technology are applied.

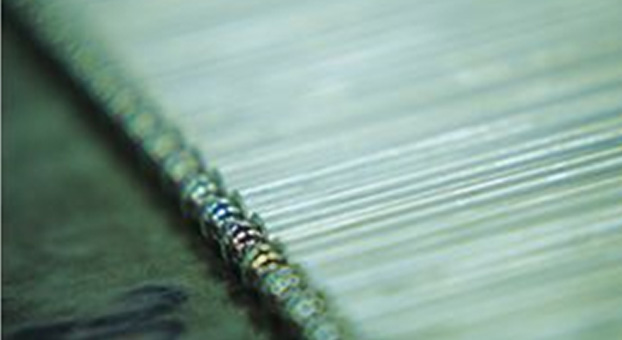

3DQ Body Frames

H-one is the world’s first company to successfully mass-produce body frames using 3DQ (Three-Dimensional Hot Bending and Direct Quench) technology, in which quenching is performed on steel tubes to enhance their material strength. Body frames produced with this method have outstanding strength at the level of 1,500 MPa, which can both increase passenger safety and reduce part weights, and also have excellent accuracy of form. Since it enables high-efficiency manufacturing without the need for dies by using ultra-strength steel tubes with complex shapes, 3DQ technology can be applied to produce a wide range of frame types. (3DQ was jointly developed with Nippon Steel Corporation and Nippon Steel Pipe Co.)

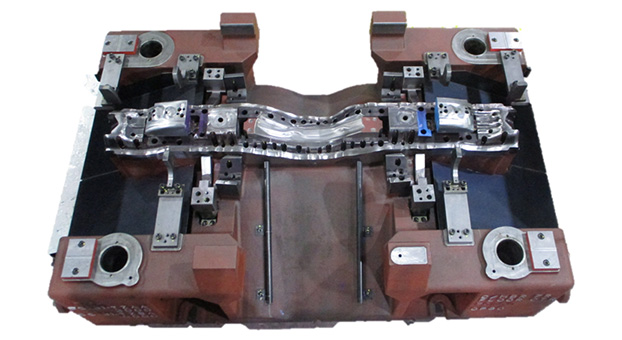

Dies and Welding Equipment

Dies

H-one Group manufactures dies in-house, and one of our Group company produces casting for dies. Our integrated production system from materials to finished products, our die production technology and our dies on the basis of expertise in high-strength material processing cultivated over the course of more than 30 years has allowed us to gain a tremendous degree of trust from both domestic and overseas customers.

Welding Equipment

H-one welding lines are designed with digital simulations, providing flexibility to enable complicated stack welding and small-volume production. The know-how that has been accumulated in our long company history has been incorporated in our proprietary welding equipment that has superior versatility, durability, and maintenancibility.

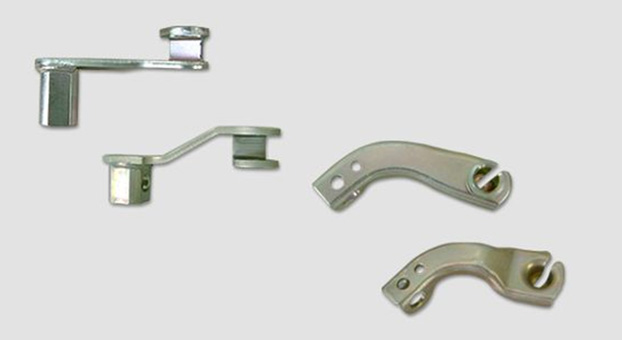

Motorcycle, Power Products, etc.

Control Levers

The engine control parts and the transmission parts, which transfer power to the wheels, are key contributors to the improvement of engine performance. H-one manufactures control levers of automatic transmissions and throttle levers that transfer on/off operations of the acceleration pedal.

Yoke Rotors

H-one manufactures yoke rotors, which are critical to inverter generators. Because the yoke rotor, which is connected to the engine, rotates very fast, this functional part requires precise machining in concentricity and circularity.

Pushrod

In 1994, H-one realized joining of steel and aluminum, which was then considered to be impossible. This dissimilar material joining technology was incorporated in the pushrods for general-purpose engines, making engines lighter and quieter.